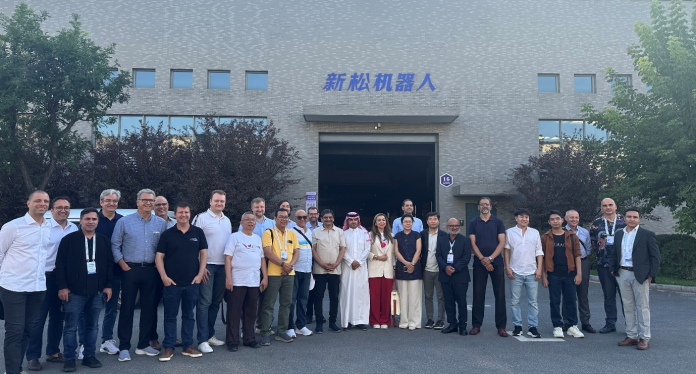

After the 2025 Global Industrial Internet Conference, organized by the China Federation of Industrial Economics, Xinhua Net, the State News Agency, and China Unicom, delegates from 30 enterprises had the opportunity to visit SIASUN, China’s largest industrial robotics manufacturing company, which was inaugurated by President Xi Jinping.

The Association of Big Data & AI (ABDI), in collaboration with Indonesian Technology & Innovation (INTI), will host the NextGen AI Summit & Expo 2025 on October 28 and 30, 2025, at JIEXPO Kemayoran, Jakarta. This national-scale event will serve as a key forum to strengthen Indonesia’s artificial intelligence (AI) ecosystem towards Golden Indonesia 2045.

Carrying the theme:

“AI Infrastructure & Governance, Data Protection, Cyber Security, Data Integrity (SDI), Government Tech (GovTechAI) Towards Golden Indonesia 2045”, the summit will bring together government officials, industry leaders, technology experts, and academia to discuss policies, infrastructure, and strategic innovations for advancing AI in Indonesia.

On the right side of the photo in SIASUN’s factory lobby is a desert in China, while the left side shows how the area has been transformed into greenery through the use of advanced technology.

The SIASUN Robotics Manufacturing Complex is vast, consisting of multiple sub-factories producing a wide variety of robots, several of which we had the opportunity to visit and discuss further. SIASUN is recognized as one of China’s strategic state-owned enterprises in the field of robotics.

Industrial Robots

SIASUN’s smart industrial robots are equipped with intelligent sensing, AI-based cognition, autonomous decision-making similar to AI Agents, and self-controlled execution. Through extensive real-world applications and process integration across diverse industries, SIASUN has launched a wide range of engineering series robots.

With more than two decades of experience in engineering application verification and thousands of project deployments, SIASUN leverages its cutting-edge technology to deliver value-added technical services. By integrating industrial robot products with customized applications, the company has earned the trust and support of customers worldwide.

Mobile Robots

SIASUN Intelligent Mobile Robotics is committed to providing advanced mobile robotic solutions for global customers. Its offerings cover the entire process—from R&D and design to manufacturing, installation, commissioning, and technical services—while delivering exceptional customization capabilities.

SIASUN is a global leader in innovative robotics technology and maintains a dominant position in the high-end market. It also pioneered the export of domestically produced robots from China. To date, SIASUN has developed more than 100 models of mobile robots across ten categories, serving diverse industries and scenarios, making it the company with the most comprehensive product lineup in the sector.

Special Robots

To meet the growing demand for customization and personalization in various industries, Xinsong Special Robots integrates advanced robotic automation technologies to develop heavy-duty hydraulic robots (with load capacities ranging from 1 to 40 tons), exoskeleton robots, drilling platform robots, and specialized robots for challenging environmental applications.

Xinsong Special Robots has established a complete industrial chain—from proprietary technologies and specialized robotic products to dedicated digital production lines. These robots have been widely adopted in key sectors of China’s national economy, including the military, national defense, marine (underwater), aerospace, and nuclear industries.

Xinsong Special Robots has established a complete industrial chain, spanning from proprietary technologies to specialized robotic products and dedicated digital production lines. Its solutions have been widely applied across key sectors of the national economy, including the military, national defense, marine (underwater), aerospace, and the nuclear industry.

Collaborative Robots (Mobile Autonomous)

Duco (DO UNIQUE COBOT) Robotics focuses on independent research, development, and production of various collaborative robots (Cobots) designed to work together, interact, and communicate within a group.

DUCO is the Cobot brand of SIASUN Robot & Automation Co., Ltd, founded in 2000 with robotics technology from the Chinese Academy of Sciences. Officially launched in Shanghai in 2014, DUCO was established as a specialized brand dedicated to the advancement of collaborative robotics.

The DUCO product line includes collaborative robots, intelligent mobile robots (DUCO AMR – Autonomous Mobile Robots), the DUCO Mind intelligent application controller, the DUCO Core operating system, and the DUCO Cloud technology platform. DUCO has pioneered several firsts in China, including the country’s first 7-axis Cobot, the first dual-arm Cobot, and high-payload Cobots capable of carrying up to 25 kg.

With more than 300 patents and independent control of its core components, SIASUN ensures technological leadership and reliability. DUCO’s CE and SEMI-certified products are characterized by intelligence, safety, and stability, making them widely adopted across industries such as automotive, energy, semiconductors, consumer electronics, food and pharmaceuticals, as well as education and research.

Today, Duco Robotics exports its products to more than 40 countries and regions, including Southeast Asia, North America, and Europe, solidifying its global reputation in collaborative robotics.

Agentic AI in SIASUN Collaborative Robots

Agentic AI refers to the capability of artificial intelligence systems to act autonomously with a specific purpose, make decisions, and adapt to their environment without constant human intervention. SIASUN integrates Agentic AI into various aspects of its collaborative robots:

- Autonomous Decision-Making

SIASUN’s collaborative robots are equipped with AI algorithms that analyze sensor data in real time, plan movement paths, and adjust actions based on environmental changes. For example, SIASUN’s mobile robots leverage SLAM (Simultaneous Localization and Mapping)technology to navigate independently in dynamic factory settings. - Natural Interaction and Contextual Understanding

Through its partnership with Baidu AI Cloud, SIASUN has developed robots capable of understanding natural language voice commands and even interpreting users’ emotions. A notable example is the Intelligent Robot Calligrapher, which can analyze voice tones and produce personalized written content. - Dynamic Task Adaptation

SIASUN’s robots can seamlessly switch between tasks without requiring extensive reprogramming. For instance, in a 5G factory in Thailand, SIASUN’s collaborative robots work alongside human operators to handle packing across two production lines simultaneously—demonstrating advanced multitasking abilities and autonomous collaboration with both humans and other Agent AI systems.

Physical AI in SIASUN Collaborative Robots

Physical AI refers to the integration of artificial intelligence with the physical body of robots, enabling direct interaction with the real world through advanced sensors, actuators, and control systems. SIASUN applies this technology through several key capabilities:

- Precision & Motion Control

Industrial robots such as the SR270A-270achieve positional repeatability of up to ±0.03 mm, powered by high-speed, high-precision motion control algorithms. Meanwhile, humanoid robots like Songyi and Songxing can reach an accuracy of ±0.05 mm in handling complex object manipulations. - Multimodal Sensing and Perception

SIASUN equips its robots with LiDAR sensors, 3D cameras, and vision systemsto recognize objects, avoid obstacles, and adapt to dynamic environments. For instance, its mobile robots in new energy factories use visual recognition systems to autonomously identify materials. - Dexterity and Complex Manipulation

SIASUN’s dual-arm humanoid platforms are capable of grasping, sorting, and assembling objects of various shapes and sizes—closely replicating the dexterity and flexibility of human hands.

Integration of Agentic AI & Physical AI in Applications

The combination of Agentic AI and Physical AI enables SIASUN robots not only to “think” autonomously but also to “act” physically with intelligence. Key applications include:

- Industry 4.0

In the automotive and new energy sectors, SIASUN’s autonomous mobile robots (AMRs)transport materials between workstations, while collaborative robotic arms perform precision assembly. These systems are fully connected to ERP platforms and cloud networks for seamless end-to-end workflow optimization. - Public Services

Robots such as the Doco Coffee Robotoperate 24/7, understanding customer voice commands and autonomously preparing beverages with high consistency. - Complex Tasks

The humanoid robot Songxingdemonstrates bipedal walking, environmental awareness through multimodal perception, and natural language interaction to support various social service functions.

Core Technology Enablers

SIASUN strengthens its AI–robotics ecosystem by independently developing critical components:

- Autonomous Control Platform

In-house control and navigation systems that process sensor data in real-time, enabling rapid and accurate decision-making. - AI Large Models

A strategic collaboration with Baidu AI Cloudprovides large-scale AI models and natural language processing capabilities, empowering smarter and more human-like human–robot interactions.

Physical AI pada Robot Kolaboratif SIASUN

Physical AI merujuk pada integrasi kecerdasan buatan dengan tubuh fisik robot, memungkinkan interaksi langsung dengan dunia nyata melalui sensor, aktuator, dan sistem kontrol canggih. Teknologi ini diterapkan SIASUN melalui:

- Presisi & Kontrol Gerakan

Robot industri seperti SR270A-270memiliki repetisi posisi hingga ±0.03 mm dengan algoritma kontrol gerakan berkecepatan tinggi dan presisi tinggi. Humanoid robot Songyi dan Songxing bahkan mampu mencapai akurasi ±0.05 mm dalam manipulasi objek yang rumit. - Sensor dan Persepsi Multimodal

SIASUN melengkapi robotnya dengan sensor LiDAR, kamera 3D, dan sistem vision untuk mengenali objek, menghindari rintangan, serta beradaptasi dengan lingkungan. Misalnya, mobile robot di pabrik new energymenggunakan visual recognition systemuntuk mengidentifikasi material secara otonom. - Ketangkasan dan Manipulasi Kompleks

Platform humanoid dual-arm SIASUN dapat menggenggam, menyortir, hingga merakit objek dengan berbagai bentuk dan ukuran, meniru fleksibilitas tangan manusia.

Integrasi Agentic AI & Physical AI dalam Aplikasi

Kombinasi Agentic AI dan Physical AI memungkinkan robot SIASUN tidak hanya mampu “berpikir” secara otonom, tetapi juga “bertindak” secara fisik dengan cerdas. Beberapa aplikasinya antara lain:

- Industri 4.0

Dalam sektor otomotif dan new energy, mobile robot otonom (AMR) SIASUN mengangkut material antar stasiun kerja, sementara lengan robot kolaboratif menangani perakitan presisi. Seluruh sistem ini terhubung ke ERP dan clouduntuk optimasi alur kerja end-to-end. - Layanan Publik

Robot seperti Doco Coffee Robotberoperasi 24/7, memahami pesanan suara pelanggan, dan secara otonom menyajikan minuman dengan konsistensi tinggi. - Tugas Kompleks

Humanoid robot Songxingdapat berjalan bipedal, memahami lingkungan dengan multimodal perception, serta berinteraksi menggunakan bahasa alami untuk mendukung layanan sosial.

Dukungan Teknologi Kunci

SIASUN memperkuat ekosistem AI-robotik melalui pengembangan komponen inti secara mandiri:

- Platform Kontrol Otonom

Sistem kontrol dan navigasi in-house yang memproses data sensor secara real-time untuk mendukung pengambilan keputusan cepat. - AI Large Models

Kolaborasi dengan Baidu AI Cloudmenyediakan kapabilitas pemrosesan bahasa alami dan model AI berskala besar untuk mendukung interaksi manusia–robot yang lebih cerdas.